PRINT TERMS TO KNOW

COLORS

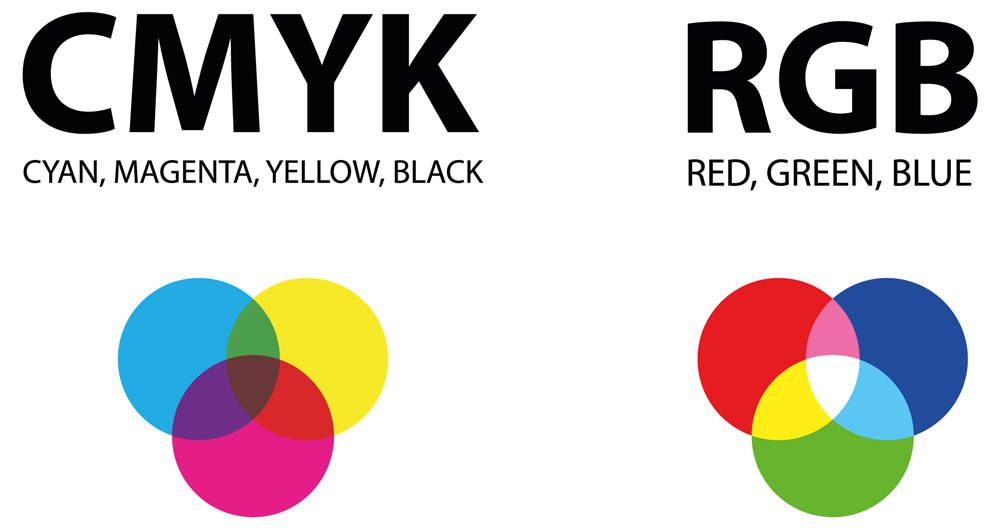

CMYK

Cyan, magenta, yellow and black. Commonly used in four color process and digital printing.

Printed materials are saved in a CMYK color profile before digitally printing a job. Cyan, magenta, yellow and black are layered in the print process to produce accurate colors.

RGB

RGB: Red, green and blue. Commonly used for digital design.

Video monitors use the RGB color model to produce images.

PMS

PMS: The Pantone Matching System is a set of universal colors that all printers can replicate. Used to improve consistency throughout print materials.

Two pantone colors are used on the Great Plains Food Bank’s trucks to ensure an exact color match to their corporate colorway and across the fleet. These colors are premixed for consistency prior to production.

DESIGN

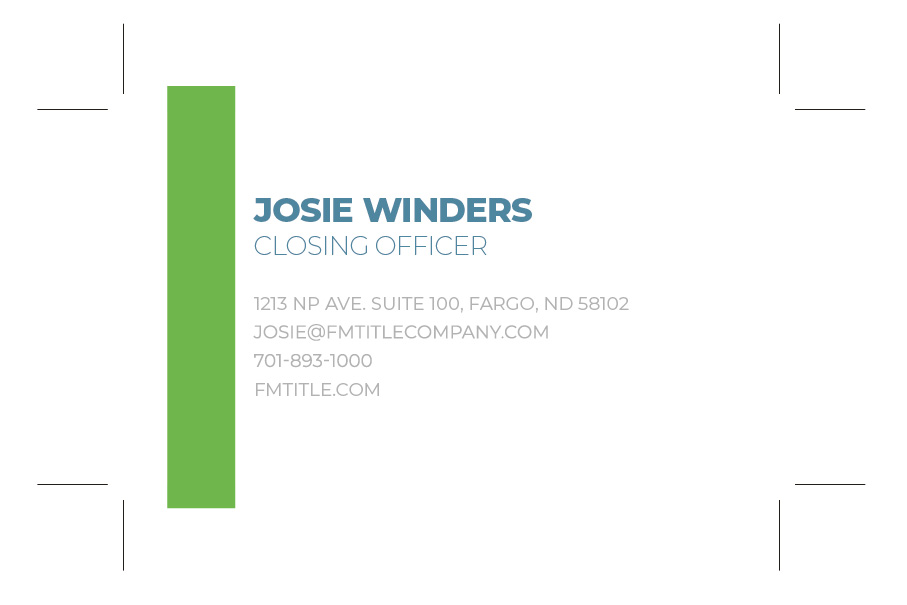

TRIM MARKS

Trim marks show the printer where to trim a large sheet to get the proper page size.

When we send FM Title’s business cards to the printer, we send a file with trim marks so the printer knows where and how to cut the card.

GUTTER

The center of a book where two pages meet.

In the ND FFA Summer Magazine, photos are designed to bridge the magazine’s gutter. Special attention is made so no faces or copy land within the crease.

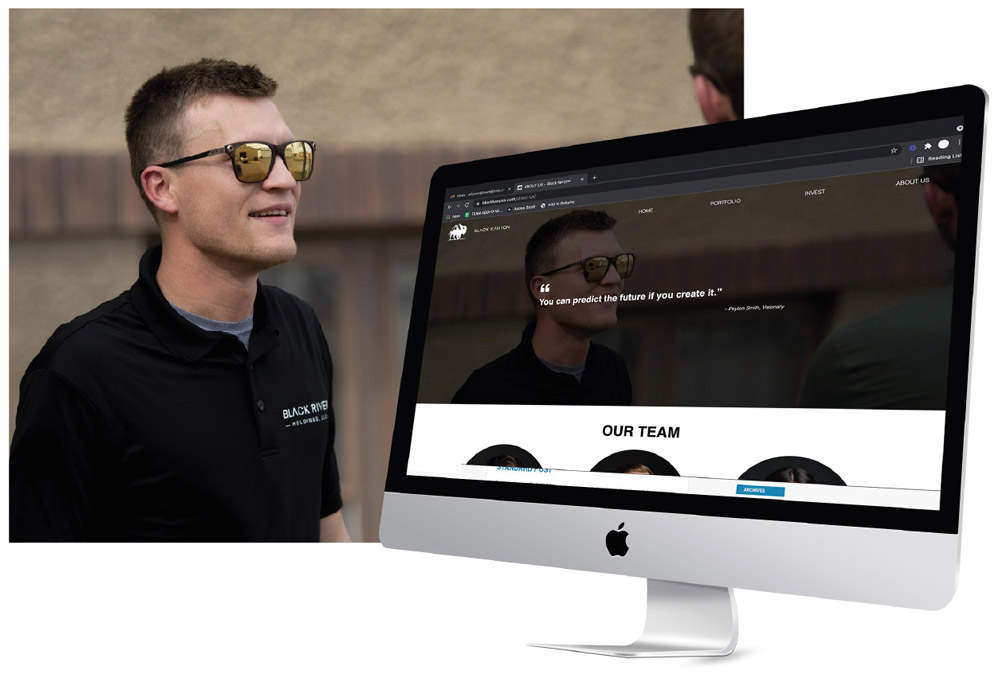

PPI/DPI

Pixels per inch, also referred to as DPI (dots per inch when assigned to print applications), represents the resolution of an image. 72ppi is optimal for digital, 300ppi is optimal for print.

Sized at 72 ppi, the website banner images on BlackKanyon.com are quick to load and look clear on your monitor. The same photos are resized to high resolution, 300 dpi, for clear printing in the company’s brochures and other printed documents.

READERS SPREADS

Show pages in two page spreads, in the correct order for someone to read the document.

This Vanity Bar proof is arranged in reader spreads for easier proofing and accurate representation of the final product.

PRINTER SPREADS

Show pages in proper order so when the document is printed, trimmed and assembled, all the pages appear consecutively.

Here, the Vanity Bar mailer is organized in printer spreads for proper assembly.

UP

A term used to describe how many similar sheets can be produced on a larger sheet; two up, three up, etc.

These Great Plains Food Bank flyers are sized to print three up on an 8.5×11 page. After trimming, three finished pieces will be created from each sheet of paper.

FINISHING

SCORE

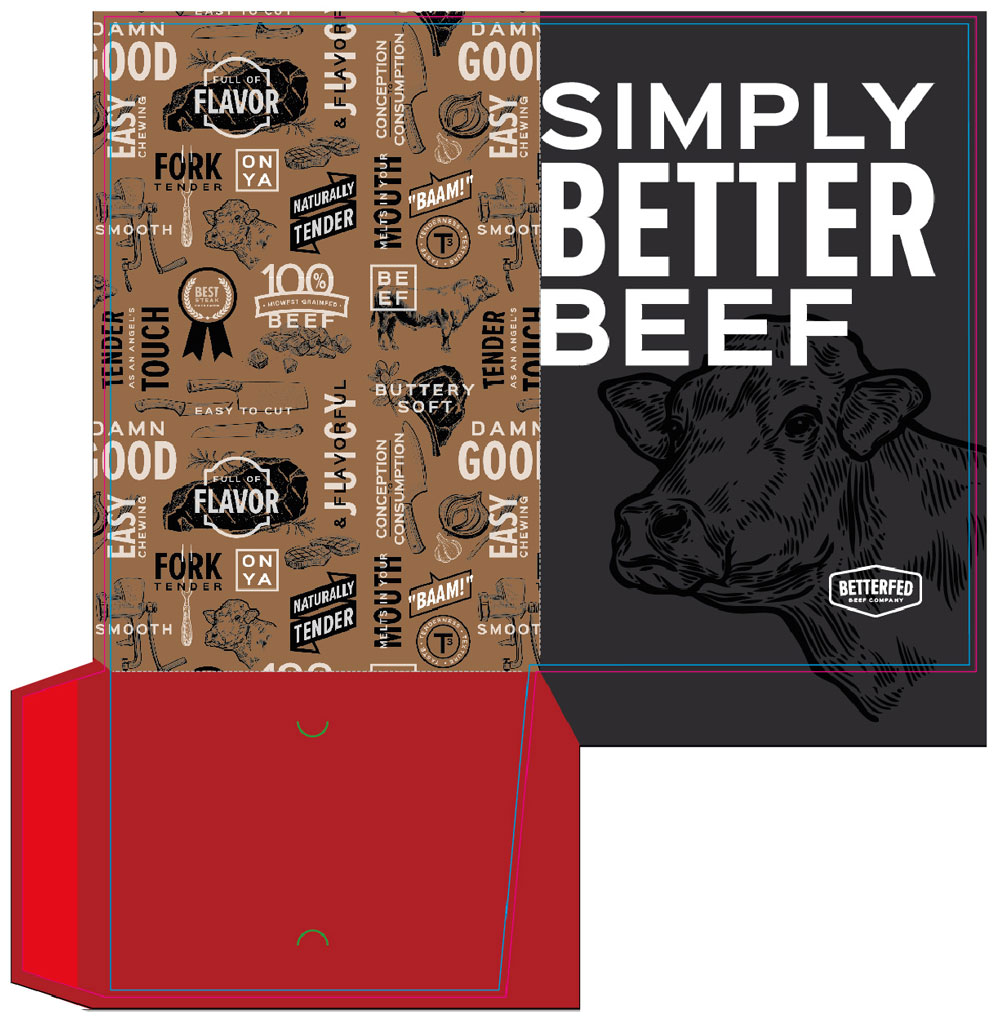

Making a crease in paper so it will fold easily and accurately.

The score line, shown on these mini-folders created for BetterFed Beef, ensures worry-free folding.

DIE CUT

Cutting materials by machine into specific shapes.

The BetterFed Beef mini folders utilized a die cut to produce a folder from a single sheet of cardstock.

PERFORATION

PERFORATION: Allows for easy separation of two sections of material.

The Great Plains Food Bank used perforation to create a tear off donation appeal at the bottom of their letterhead.

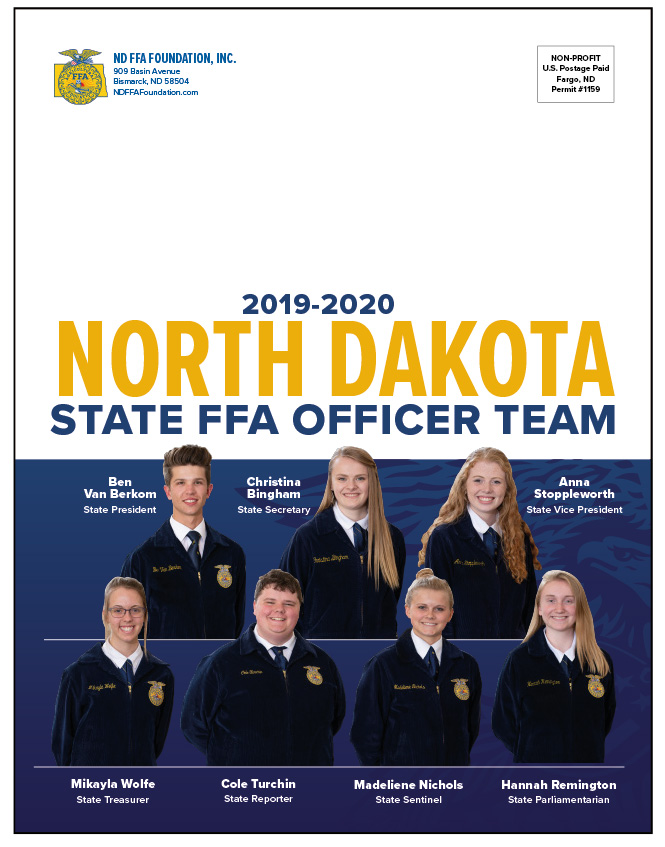

INDICIA

INDICIA: Markings preprinted on mailed materials to replace the stamp.

By using the printer’s indicia, the North Dakota FFA Foundation’s newsletter went directly from printing to the mail stream, keeping the job efficient and on time.

EMBOSS

EMBOSS: Creating raised letters or designs in print.

The embossed logo on our letterhead creates an elegant and official look.

DEBOSS

DEBOSS: Creating recessed letters or designs in print.

We used a leather stamp to deboss The Bunker’s logo into wallets that were used as gifts for their customers and clients.

PAPER

COATED PAPER

COATED PAPER: Paper is coated for a specific result such as sheen or feel. Coated papers have improved reflectivity, ink coverage and stability. Common types: gloss or matte.

Abovo chose high gloss coated paper for BetterFed Beef’s product insert card. The coating stands up well to moisture, ensuring the message is delivered in perfect condition along with their frozen product.

UNCOATED PAPER

UNCOATED PAPER: Paper without a coating to fill in between the fibers.

Printed on an uncoated kraft box, ink soaks into the paper and gives BetterFed Beef’s logo a rich, dull appearance.

PRINTING

DOT GAIN

DOT GAIN: When ink is absorbed into paper during the printing process.

Seen commonly in newsprint, dot gain creates a muddy look when a dot of ink actually grows as it soaks into the porous newsprint paper. If many dots are close together, they will bleed into each other, creating a dark appearance.

DIGITAL PRINTING

Also known as four color process printing, digital printing is designed for use with CMYK color. Frequently used for small-volume print jobs ranging from 1 to 5,000 sheets of paper.

When Daily’s Market needed a new sign for their basket display, Team Abovo used digital printing, allowing for a cost-effective, quick turnaround on the single sign.

BLEED

BLEED: Adding an extra amount of image or background beyond the trim area of your printing piece.

The cover of the ND FFA Summer Magazine has full bleed. Here, a 1/8” bleed was added to the outer edge of the page. This extra was trimmed off, eliminating a margin and allowing printed color to run all the way to the edges of the cover.

OFFSET PRINTING

OFFSET PRINTING: For high-volume jobs. Colors are set up on plates with prints running through each color to create the finished product. Allows for both CMYK and PMS color options.

Using an offset printer is cost effective for large print jobs, such the ND FFA Foundation’s Annual Report.

OVERRUN

OVERRUN: Surplus of copies printed.

When The Vanity Bar ordered their direct mail piece, we added an overrun to the order so extra copies could be available on location.

Whether you’re starting a new print project, working with different materials, or just curious to learn more, it’s good to know industry terms to ensure you and your printer are on the same page, literally. And, you can always rest assured that Team Abovo and your local printer are here to help.